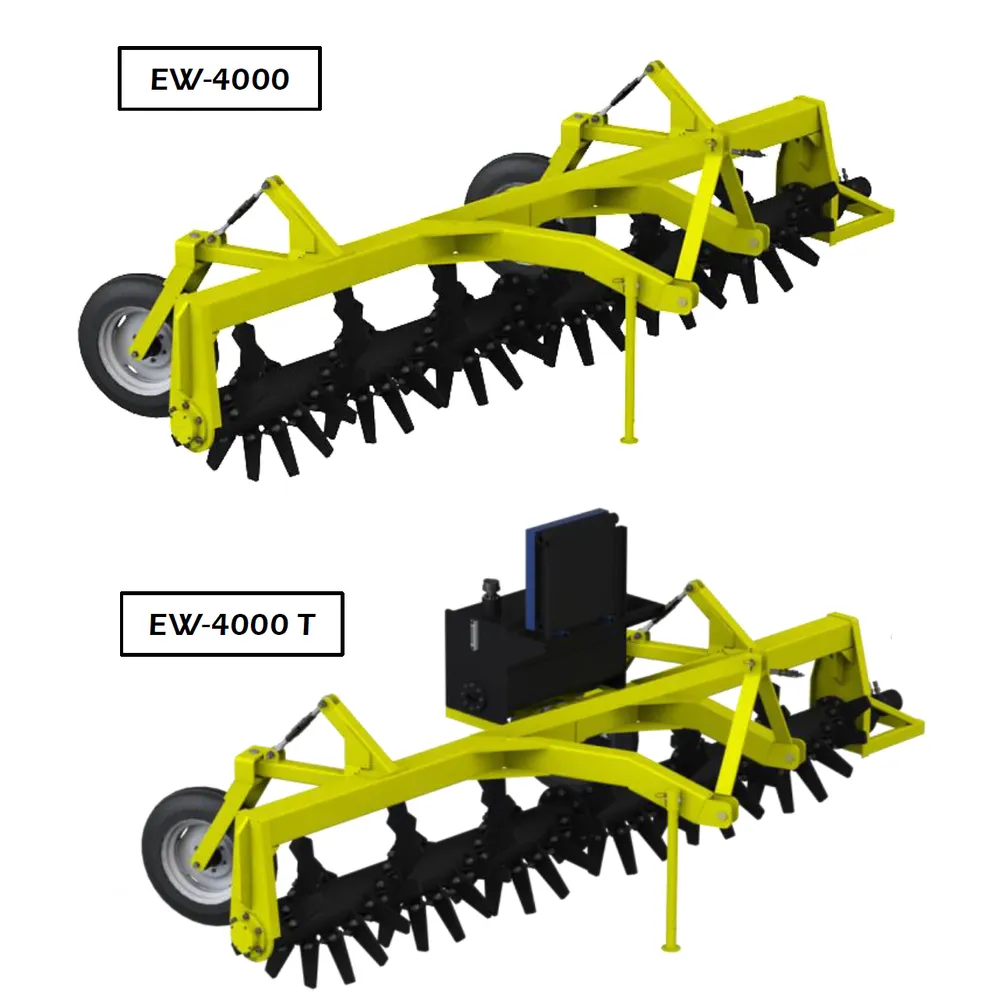

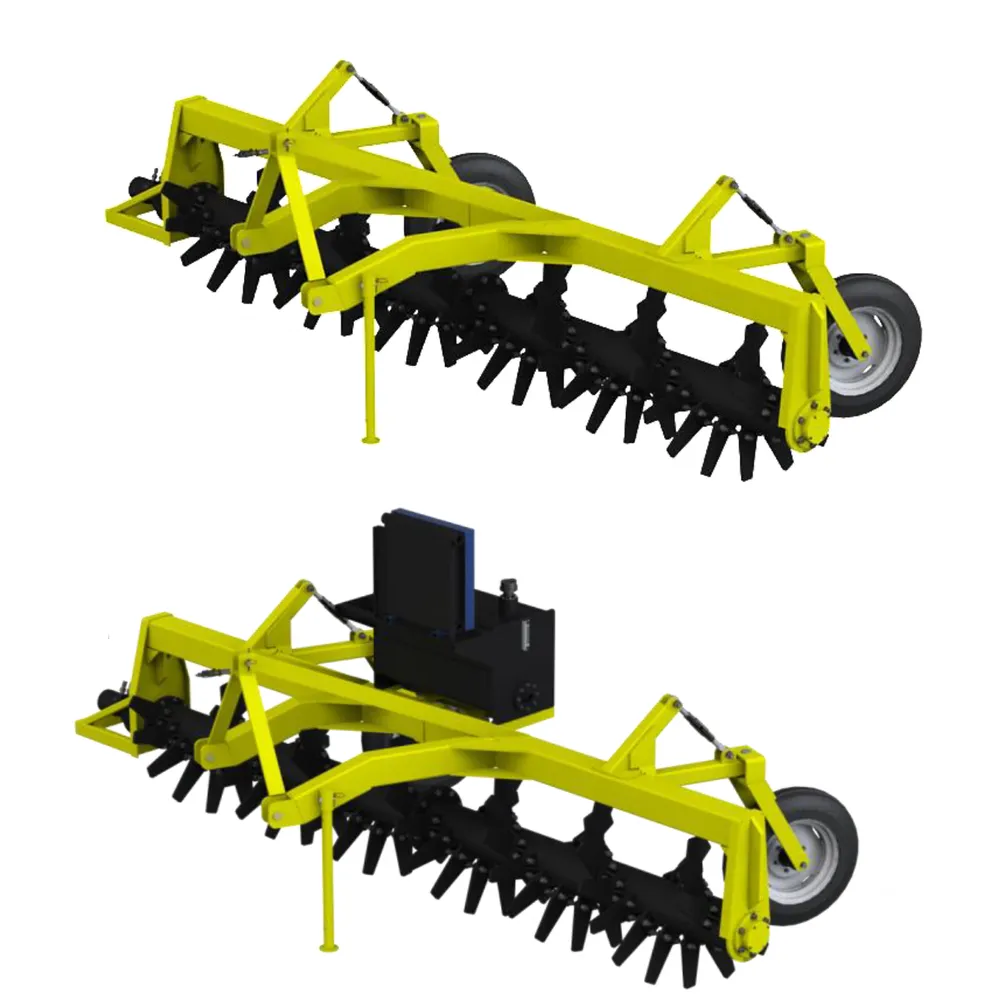

EW-4000 Rock Rake for Tractor

Discover the EW-4000 tractor rock rake, a robust 3 point hitch attachment designed for efficient stone removal and soil preparation on rugged terrains. With a 3.6m working width and compatibility for tractors up to 100 cv, this heavy duty rock rake ensures smooth operation at 3-5 km/h, minimizing downtime. Ideal for agricultural and landscaping tasks—contact Mexico Watanabe for custom options and reliable performance backed by durable construction.

EW-4000 Tractor Rock Rake Overview

The EW-4000 tractor rock rake stands out as a versatile attachment engineered for demanding land management tasks. This three point rock rake integrates seamlessly with standard tractors, facilitating the efficient gathering and removal of rocks, debris, and uneven soil clumps. Built with high-strength materials, it addresses the challenges faced by farmers and landscapers in rocky environments, ensuring smoother surfaces for planting or construction. Its design emphasizes durability, making it suitable for prolonged use without frequent repairs. Operators appreciate how this rock rake tractor attachment transforms uneven terrain into workable ground, reducing manual labor and enhancing productivity across various scales of operations.

The EW-4000 model excels in scenarios where traditional methods fall short. For instance, in agricultural settings, it prepares fields by windrowing stones to one side, preventing damage to other equipment like plows or harvesters. This PTO rock rake for tractor variant, while primarily hydraulic-driven, complements PTO systems in compatible setups, offering flexibility for different tractor configurations. Users in Mexico, where diverse soil types from volcanic regions to arid plains prevail, find it particularly effective. The machine's robust frame withstands impacts from large stones, and its adjustable features allow customization to specific job requirements.

Product Specifications

If your project requires modifications or additional features beyond these standard specifications, please contact our team at Mexico Watanabe for tailored solutions to fit your needs.

| Technical Data | Grabie do kamieni EW-4000 |

|---|---|

| Dimensions | |

| Length (mm.) | 4550 |

| Width (mm.) | 2400 |

| Height (mm.) | 1380 |

| Weight | 1800 kg |

| Bottom linkage category | 2 |

| Working Width | 3.6 m |

| Tractor requirements | |

| Engine power (min.) | 100 cv |

| Oil flow (min.) | 60 L/min. |

| PTO Speed | 540 rpm |

| Working speed | 3 – 5 km/h |

| Required control valves | 2 |

Features of the EW-4000 Rock Rake for Tractor

- Reinforced Steel Frame Construction

Crafted from premium-grade steel alloys, the EW-4000's frame delivers exceptional resistance against rust and abrasion in demanding outdoor settings, guaranteeing extended service life even during operations involving heavy stone clusters and rough landscapes, which helps maintain structural integrity over years of intensive use. - Customizable Tine Angle Adjustments

Operators can fine-tune the tine positions on the EW-4000 to suit various tasks, from gentle surface smoothing to aggressive debris removal, providing versatility that adapts to different soil types and job intensities while ensuring precise control and optimal results without unnecessary equipment swaps. - Integrated Safety Guards for Moving Components

Protective shields enclose all dynamic elements of the EW-4000, minimizing risks of accidental contact during fieldwork, which promotes a safer working environment for tractor drivers and ground crews, aligning with industry standards for hazard prevention in agricultural machinery. - Seamless Hydraulic System Integration

The hydraulic setup in the EW-4000 enables effortless management of rake functions directly from the tractor cab, avoiding overload on the vehicle's systems and ensuring steady performance across uneven terrains, which translates to fewer interruptions and smoother daily operations for users. - Reliable Power Transmission via PTO Option

When configured with PTO capabilities, the EW-4000 rock rakes maintain uniform energy distribution to prevent gaps in rock collection on challenging surfaces, supporting consistent output that enhances overall task efficiency and reduces the need for repeated passes over the same area. - Durable Wheels with Puncture-Resistant Tires

Equipped with robust wheels featuring tires engineered to withstand sharp objects and irregular ground, the EW-4000 offers superior stability during movement, allowing operators to navigate rough fields confidently while cutting down on fatigue from prolonged sessions behind the wheel. - Quick-Release Coupling Mechanisms

The EW-4000 includes fast-detach connectors that simplify mounting and dismounting processes, saving crucial time at job sites and enabling quick transitions between tools, which is particularly beneficial for professionals handling multiple attachments in a single workday. - Advanced Vibration Reduction Technology

Incorporating specialized dampening systems, the EW-4000 lessens oscillations transmitted to the tractor and operator, extending the lifespan of parts and boosting comfort levels, as noted by experienced field workers who achieve greater coverage without the strain of constant shaking.

How Does a Tractor PTO Rock Rake Work

A tractor PTO rock rake operates as a specialized attachment designed to clear stones and debris from soil surfaces, primarily in agricultural and landscaping applications. Mounted via a three-point hitch system at the rear of the tractor, the rake connects to the tractor's power take-off (PTO) shaft, which transmits rotational energy from the engine to drive the rake's internal mechanisms. This setup allows the rake to function independently of the tractor's forward motion, ensuring consistent performance across varying terrains.

The primary working principle revolves around a series of hardened tines or teeth arranged on a rotating drum or bar. As the tractor advances at a controlled speed—typically between 3 to 5 kilometers per hour—the PTO engages the drum, causing it to spin. This rotation enables the tines to penetrate the top layer of soil, agitating it to dislodge embedded rocks, roots, and clumps. The design incorporates a slight forward tilt, which helps lift the separated materials without excessive excavation, thereby preserving the underlying soil structure and minimizing erosion risks.

Hydraulic components play a crucial role in enhancing control and efficiency. Oil flow from the tractor's hydraulic system powers cylinders that adjust the rake's angle and depth in real time. Operators can modify these settings from the cab, directing the collected debris into neat windrows along one side of the path. This angling prevents overloading the drum and ensures balanced pressure distribution, avoiding unnecessary strain on both the equipment and the ground. For models equipped with advanced PTO configurations, the rotational energy also supports auxiliary features, such as variable speed controls on the drum, which optimize force application across the full working width—often up to 3.8 meters in larger units like the EW-4000.

The process begins with attaching the PTO shaft securely, engaging the tractor's PTO at a recommended RPM (usually around 540), and lowering the rake to the desired height. As the tractor moves, the spinning tines sift through the soil, flinging smaller particles back while larger rocks are guided into rows for subsequent removal. This method not only streamlines land preparation but also reduces manual labor, making it ideal for tasks like field grooming before planting or site leveling for construction.

Select the Right Heavy Duty Rock Rake for Your Needs

- Length Considerations for Compatibility and Maneuverability

Evaluate the overall length of the rock rake, such as the 4300 mm for the EW-4000 model, to confirm it aligns with your tractor's turning radius and storage space requirements, preventing issues during tight field turns or when transporting the equipment on trailers, while ensuring safe operation in confined agricultural areas without compromising efficiency. - Width Assessment for Transport and Storage

Examine the width dimension, like the 1380 mm in the EW-4000, to determine ease of road transport and gate passage, as narrower designs facilitate compliance with local regulations and reduce the risk of damage during movement, allowing seamless integration into existing farm infrastructure without necessitating additional modifications. - Height Evaluation for Clearance and Safety

Review the height profile of the rock rake, though specific measurements may vary by model, to guarantee sufficient ground clearance during operation and compatibility with tractor lift heights, avoiding potential collisions with low-hanging branches or structures and promoting stable attachment for secure fieldwork performance. - Weight Analysis for Tractor Stability

Assess the equipment weight, exemplified by the 1800 kg of the EW-4000, against your tractor's lifting capacity and ballast setup to maintain balance and prevent front-end lift-off, which supports safer handling on slopes and uneven ground, ultimately extending the lifespan of both the rake and the vehicle. - Working Width Selection for Productivity Needs

Choose a working width, such as the 3.8 meters offered by the EW-4000, based on your field size and desired coverage per pass, enabling faster clearance of rocks over larger areas while matching the scale of your operations to optimize time and fuel consumption without overloading the system. - Engine Power Requirements for Optimal Performance

Match the minimum engine power, like the 300 cv needed for the EW-4000, to your tractor's horsepower output to ensure consistent power delivery during demanding tasks, preventing engine strain and enabling smooth rock separation in dense soils, which contributes to reliable daily use in professional settings. - Oil Flow Specifications for Hydraulic Efficiency

Verify the required oil flow rate, such as 60 liters per minute for the EW-4000, against your tractor's hydraulic system capabilities to facilitate precise angle adjustments and consistent operation, reducing wear on components and enhancing control over debris management in varied terrain conditions. - Working Speed Guidelines for Effective Operation

Factor in the recommended working speed range, typically 3-5 km/h as with the EW-4000, to balance thorough rock removal with timely completion of tasks, adjusting based on soil type and stone density to minimize soil disruption and achieve uniform results across the prepared surface. - PTO Input Speed Compatibility for Power Transmission

Confirm the PTO input speed, often standardized at 540 RPM for rock rake, to align with your tractor's PTO output for efficient energy transfer, supporting auxiliary functions and preventing mechanical mismatches that could lead to reduced performance or equipment failure.

Application Areas

1. Field Preparation in Crop Farming Operations

Farmers deploy the EW-4000 rock rake for tractor to methodically eliminate stones and uneven clumps from arable land prior to planting seasons, safeguarding delicate seeding equipment from potential breakage. This process not only smooths the soil bed but also promotes uniform seed distribution, leading to healthier crop emergence and higher yields in regions with stony subsoils, such as those found in volcanic or glacial deposit areas common in parts of Mexico and similar terrains worldwide.

2. Row Maintenance in Orchards and Vineyards

In fruit-growing setups like apple orchards or grape vineyards, the attachment excels at keeping inter-row spaces free of debris and rocks, which facilitates better airflow and sunlight penetration to the plants. By doing so, it supports integrated pest management strategies by reducing hiding spots for insects and rodents, while also improving irrigation efficiency through leveled ground that prevents water pooling, ultimately contributing to sustained plant health and easier harvesting routines over multiple seasons.

3. Site Leveling for Construction Projects

On building sites, the EW-4000 serves as a practical tool for initial ground conditioning, where it removes obstructive rocks and levels surfaces ahead of foundation laying or road paving activities. This step minimizes delays caused by unexpected subsurface hazards, ensures stable bases for structures, and reduces the need for additional manual labor, making it a favored choice among contractors handling urban expansions or rural infrastructure developments that demand precise terrain management.

4. Landscape Enhancement in Parks and Recreational Areas

Landscaping professionals utilize this rock rake tractor implement to groom public spaces, such as municipal parks or golf courses, by clearing away stones to create flat, safe surfaces suitable for sod laying or pathway construction. The result is aesthetically pleasing environments that resist erosion, support turf root establishment, and require less ongoing upkeep, enhancing visitor safety and enjoyment in community green spaces while aligning with municipal standards for durable outdoor designs.

5. Reclamation Efforts in Degraded Lands

For environmental restoration projects, including post-mining site recovery or erosion-prone hillside rehabilitation, the EW-4000 aids in sorting out rocky materials to restore soil usability. It allows for the reintroduction of vegetation by preparing the ground for native plant seeding, helping to stabilize slopes and prevent further land degradation, which proves valuable in ecological initiatives aimed at biodiversity conservation and sustainable land use practices.

FAQs

Q: What is a tractor rock rake used for?

A: Operators rely on a tractor rock rake primarily for removing stones, roots, and assorted debris from soil surfaces, setting up fields for seeding, construction, or landscaping projects. This attachment gathers materials into organized windrows, simplifying their disposal and enhancing overall ground quality for better crop establishment or site development, making it indispensable in rugged terrains where manual clearance proves inefficient.

Q: How does a rock rake for tractor differ from a standard landscape rake?

A: A rock rake for tractor, such as the EW-4000 model, sets itself apart from conventional landscape rakes through its reinforced tines built for enduring impacts and integrated hydraulic systems that enable precise handling of substantial rocks. This design suits intensive applications, unlike lighter landscape versions meant for superficial grooming, offering greater durability and control for demanding agricultural or land preparation tasks.

Q: Is the EW-4000 three point rock rake compatible with my tractor?

A: The EW-4000 three point rock rake works seamlessly with tractors that feature a category 2 bottom linkage setup, requiring at least 300 cv of engine power and a hydraulic oil flow of no less than 60 liters per minute. Always verify your equipment's specifications against these criteria to ensure stable performance and avoid operational mismatches during fieldwork.

Q: What maintenance is required for a PTO driven rock rake?

A: For a PTO driven rock rake like the EW-4000, essential upkeep involves applying lubricant to pivot points and joints every few weeks, conducting visual checks on tines for bends or fractures, and thoroughly rinsing off accumulated dirt after each session to ward off corrosion and maintain smooth functionality over extended periods.

Q: Where can I find a rock rake for sale in Mexico?

A: In Mexico, rock rake for sale options include direct purchases from Mexico Watanabe, where the EW-4000 model is available with various customization features tailored to local needs, along with reliable shipping services covering urban and rural areas to support farmers and landscapers seeking quality attachments.

Q: How to install a 3 point hitch rock rake safely?

A: To safely install a 3 point hitch rock rake such as the EW-4000, begin by positioning the tractor's linkage arms to match the rake's mounting brackets, fasten all pins securely, and then connect hydraulic hoses while double-checking for leaks before running a low-speed test in an open space to confirm stability.

Q: What are the advantages of a tow behind rock rake?

A: A tow behind rock rake offers expanded reach for covering vast expanses efficiently, providing adaptability in open fields where maneuverability is key, although the EW-4000 emphasizes three-point mounting for superior precision and tractor integration, which enhances control during detailed stone removal operations compared to towed alternatives.

Q: Can the heavy duty rock rake handle volcanic rocks?

A: Yes, the heavy duty rock rake in the EW-4000 configuration is engineered to manage tough volcanic rocks prevalent in Mexican landscapes, thanks to its sturdy frame and resilient tines that withstand high-impact encounters, ensuring consistent debris separation without compromising the attachment's structural reliability in challenging geological settings.

Q: What is the working principle of a PTO rock rake for tractor?

A: The working principle of a PTO rock rake for tractor involves harnessing the tractor's rotational output to spin a drum fitted with tines that dig lightly into the soil, elevating rocks and channeling them into side rows through hydraulically controlled tilts, which promotes even force application and effective clearance across the designated path.

Q: Does the EW-4000 PTO rock rake require special tools for maintenance?

A: The EW-4000 PTO rock rake generally calls for standard workshop tools like wrenches and grease guns for most upkeep procedures, though handling hydraulic components might necessitate specialized knowledge or equipment from a technician to address seals or pressure issues accurately and safely.

Customer Reviews After Purchase

Maria Gonzalez, Agricultural Engineer, Mexico

I've been running the EW-4000 tractor rock rake on our 50-hectare spread for about six months, and it's made a huge difference in prepping rocky spots for maize planting. With its 3.8m working width paired to our 320 cv machine, it zips through tough stones no problem, and the sturdy build hasn't shown any wear yet. When we hit a small glitch, Watanabe's service jumped right in with a quick fix—totally reliable, I'd tell anyone looking for a rock rake for tractor to grab this one.

Carlos Ramirez, Landscaper, United States

This heavy duty rock rake has totally revamped our site prep routine; we've tackled more than 20 jobs in the past year without a single hiccup. Shipping from Mexico arrived in just under two weeks, which kept our schedule on track. The hydraulic tweaks are straightforward, cutting down adjustment time big time, and it's held up great on varied grounds—definitely a solid pick if you're after a 3 point hitch rock rake that delivers day in and day out.

Ana Torres, Farm Owner, Argentina

Switching to the EW-4000 after some budget models was the best move; it's tough as nails and glides over our bumpy pampas without effort. The support crew nailed our installation questions in under an hour, showing real care. We've noticed way less damage to our plows since using this rock rake tractor attachment for the last eight months, especially with its adjustable tines handling uneven soil like a champ.

Diego Lopez, Construction Supervisor, Brazil

The standout quality of this PTO rock rake shines through in road base work—I've used it for three months straight, windrowing junk efficiently every time. Delivery hit the mark exactly on schedule, and their maintenance tips have kept everything humming along fresh. For the price, it's unbeatable performance, particularly when you need a tow behind rock rake option that doesn't quit under pressure.

Elena Vargas, Orchard Manager, Italy

What impressed me most was the service vibe; they tweaked the tine setup just for our rocky vineyards without fuss. After a full year hooked to our 300 cv tractor, the EW-4000 three point rock rake hasn't skipped a beat, boosting soil drainage noticeably. It's made orchard upkeep smoother, and I'd recommend it to anyone scouting a PTO driven rock rake for similar setups.

Javier Mendoza, Rancher, Australia

Logistics ran like clockwork, and this rock rake for sale exceeded what I expected in toughness—it's endured dusty outback runs for over a year, clearing stones flawlessly. The easy hook-up details make swapping attachments a breeze on busy days, and paired with our rig, it's proven essential for keeping pastures clean without extra hassle.

Pierre Dubois, Vineyard Operator, France

The EW-4000 rock rake tractor has been a reliable workhorse in our hilly vineyards for nine months, with its 1800 kg frame providing the stability needed for sloped terrain. Customer service sorted a custom part request overnight, which minimized downtime during peak season. If you're in the market for a PTO rock rake for tractor that handles fine adjustments well, this one's a keeper for quality and responsiveness.

Hans Schmidt, Field Manager, Germany

We've integrated the EW-4000 heavy duty rock rake into our operations for four months, and its precision in separating debris from clay-heavy soils has cut prep time in half. The team's logistics ensured arrival within a week, beating expectations for international shipping. With consistent performance at 3-5 km/h speeds, it's reduced wear on our other gear—solid choice for anyone needing a durable 3 point hitch rock rake.

Robert Jenkins, Crop Farmer, Canada

Hooking up the EW-4000 PTO rock rake to our setup transformed rocky field clearing over the last ten months; the hydraulic controls make on-the-fly changes simple, even in freezing conditions. Support was spot-on with troubleshooting a minor issue via email in hours. For folks searching a rock rake for tractor that stands up to harsh winters, this model's build and efficiency make it worth every penny.

Informacje dodatkowe

| Edited by | Yjx |

|---|